Design Specifications

- Flange : As per ANSI B16.5 / B 16.42

- Face to Face : As per ANSI B 16.5 #150

- Lining Thickness : 3 to 5 mm

- Other Flange Drillings like, DIN 2632 / 2633, BS 10 Table D, E or F are also available on request.

- Material

- Dimensional

- Test & Inspection

Housing Material Options

- Ductile Iron GGG40.3 / ASTM A395

- Cast Steel ASTM A216 Gr.WCB

- Steel Fabrication – ASTM A106 Gr.B SCH-40 Pipe.

Lining Material Options

- FEP – ASTM D 2116

- PFA – ASTM D 3307

- PVDF – ASTM D 3322

- PP – ASTM D 4101

- HDPE

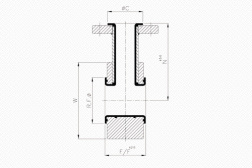

Dimensional Data

| ANSI #150 Flanged 25 NB BRANCH [ØC = 51 mm] | ||||

| SIZE | F/F (mm) | N(mm) | R.F.Ø (mm) | W (mm) |

| DN25-1” | 51 | 89 | 51 | 66 |

| DN40-1 1/2” | 51 | 102 | 73 | 85 |

| DN50-2” | 51 | 141 | 92 | 104 |

| DN80-3” | 51 | 160 | 127 | 136 |

| DN100-4” | 51 | 179 | 157 | 174 |

| DN150-6” | 51 | 205 | 216 | 222 |

| DN200-8” | 51 | 237 | 270 | 279 |

| DN250-10” | 51 | 264 | 323 | 339 |

| DN300-12” | 51 | 302 | 381 | 409 |

| ANSI #150 Flanged 40 NB BRANCH [ØC = 73 mm] | ||||

| SIZE | F/F (mm) | N(mm) | R.F.Ø(mm) | W mm) |

| DN40-1 1/2” | 76 | 102 | 73 | 85 |

| DN50-2” | 76 | 141 | 92 | 104 |

| DN80-3” | 76 | 160 | 127 | 136 |

| DN100-4” | 76 | 179 | 157 | 174 |

| DN150-6” | 76 | 205 | 216 | 222 |

| DN200-8” | 76 | 237 | 270 | 279 |

| DN250-10” | 76 | 264 | 323 | 339 |

| DN300-12” | 76 | 302 | 381 | 409 |

Test & Inspection Data

- Resins are confirming to the requirements of ASTM F1545-97 (2003)

- Hydraulic Test : 29 Kg/Cm2 After Lining

- Spark Test : 15 KV D.C After Lining

Technical Information subject to change without notice.

Connect with Us