Design Specifications

- Flange : As per ANSI B16.5 / B 16.42

- Face to Face : As per ANSI B 16.5 #150

- Lining Thickness : 3 to 5 mm

- Other Flange Drillings like, DIN 2632 / 2633, BS 10 Table D, E or F are also available on request.

- Material

- Dimensional

- Test & Inspection

Housing Material Options

- Ductile Iron GGG40.3 / ASTM A395

- ASTM A234 GR. WPB

- Cast Steel ASTM A216 Gr.WCB

Lining Material Options

- PTFE – ASTM D 4895

- FEP – ASTM D 2116

- PFA – ASTM D 3307

- PVDF – ASTM D 3322

- PP – ASTM D 4101

- HDPE

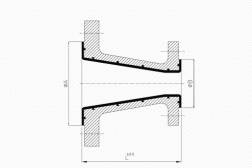

Dimensional Data

| Major Size | Minor Size (mm) | R.F (mm) | ||

| ØA | ØB | |||

| DN25-1” | DN15 | 114 | 51 | 35 |

| DN40-1 1/2” | DN25 | 114 | 73 | 51 |

| DN50-2” | DN25 | 127 | 92 | 51 |

| DN50-2” | DN40 | 127 | 92 | 73 |

| DN65-2 1/2” | DN50 | 140 | 108 | 92 |

| DN80-3” | DN25 | 152 | 127 | 51 |

| DN80-3” | DN40 | 152 | 127 | 73 |

| DN80-3” | DN50 | 152 | 127 | 92 |

| Major Size (mm) | Minor Size (mm) | L

(mm) |

R.F (mm) | |

| ØA | ØB | |||

| DN100-4” | DN25 | 178 | 157 | 51 |

| DN100-4” | DN40 | 178 | 157 | 73 |

| DN100-4” | DN50 | 178 | 157 | 92 |

| DN100-4” | DN80 | 178 | 157 | 127 |

| DN150-6” | DN50 | 229 | 216 | 92 |

| DN150-6” | DN80 | 229 | 216 | 127 |

| DN150-6” | DN100 | 229 | 216 | 157 |

| DN200-8” | DN100 | 279 | 270 | 157 |

| DN200-8” | DN150 | 279 | 270 | 216 |

| DN250-10” | DN150 | 305 | 324 | 216 |

| DN250-10” | DN200 | 305 | 324 | 270 |

- Consult “Hi-Tech Applicator” for vacuum services. Special Heavy Duty PTFE Liners vailable for full vacuum. Details can be provided on request. Other Flange Drillings like, DIN 2632 / 2633 , BS 10 Table D, E or F are also available on request.

- Max. Length available : 3 Mtr.

- Tolerance : ±3.5mm (0 to 1 Mtr.) and ±5.0mm (1 to 3 Mtr.)

- Clear ID for HDPE/PP Lined Pipes (DN/ID): 25/18 , 40/32 , 50/42 , 65/57 , 80/67

Test & Inspection Data

- Resins are confirming to the requirements of ASTM F1545-97 (2003)

- Hydraulic Test : 29 Kg/Cm2 After Lining.

- Spark Test : 15 KV D.C After Lining.

Technical Information subject to change without notice.

Connect with Us